When designing trusses, do you often include joint connections in the main design, or is it more an afterthought once the main structural members are selected based on strength? Often times, engineers will focus on minimizing the weight of the truss members, without regard to the joint design details, and this can prove to be a costly error.

In the January 2019 SE University session, Brad Fletcher, SE, from Atlas Tube, gave a presentation on HSS Truss Connections: The Ts, Ks, and Ys of It All. Brad reviewed ways that HSS truss joint configurations affects the strength and stiffness of the overall truss, as well as how the fabrications costs of the truss relate to the truss joints rather than simply the overall weight of the truss.

Brad highlighted some important rules of thumb which can be used to design efficient trusses. As a general rule, Brad suggested aiming to design chord members to be relatively stocky (low D/t or B/t) while branch members should have a larger diameter, but thinner walls (high D/t or B/t). Using this recommendation, you can avoid “thick to thin” welding and an added benefit of less surface area at the chord to reduce painting costs.

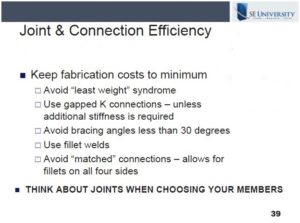

Brad also offered some additional pointers to keep fabrication costs low, as shown in the slide below. As he points out, engineers often focus only on reducing the steel tonnage of their trusses, however, there are many ways to design a less costly truss by considering the joints specifically when designing the overall truss.

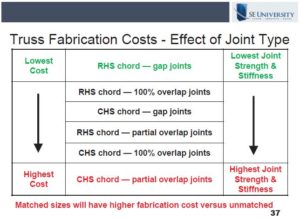

When a more costly truss connection is necessary to improve strength or stiffness values, Brad offered the following step-wise approach to consider costs while improving strength. As you can see in the slide, using Rectangular Hollow Section chords with gap joints have the lowest costs and lowest strength and stiffness values, while Circular Hollow Section chords with partial overlap joints have the highest costs and highest strength and stiffness values.

Taking steps to avoid costly Complete Joint Penetration welds and overlapped joints can often save more than solely minimizing the overall chord and web member sizes. These guidelines presented are a great starting point to begin an efficient design which considers the effect of joint configuration on the cost of the truss.