Have you encountered a design where you just can’t seem to make a stud pack work sensibly without using an over the top amount of studs or having to increase the thickness? When is it appropriate to stick with a cold-formed stud pack, and when should you consider using another option such as an HSS section?

In the May 2019 SE University session, Roger LaBoube, PhD, PE, from Missouri University of Science and Technology, presented Built-Up Member Design (Cold-Formed Steel). During the session, Roger reviewed the applicable cold-formed steel standards for framing members vs. other cold-formed applications, discussed economical solutions for stud packs, and walked through a design example of a built-up box beam that is not specifically enabled by the current design standards.

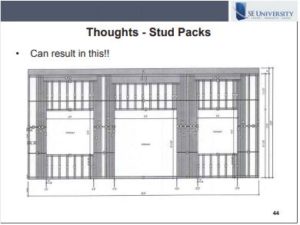

D110 presents a design solution which results in each jamb stud in the stud pack having the same tributary area as a typical stud. However, as Roger pointed out, this can lead to an inefficient design in some cases, as shown below:

Roger provided some guidance on whether stud packs or HSS sections might be most appropriate, based on the advice of other practicing engineers. First, each job may vary based on contractor preference or restrictions due to union regulations on some job sites. Another engineer noted, it tends to be more efficient to use HSS in place of larger S200 studs or heavy gauge 97-mil which will have to be welded. Also, HSS may be a better option when 3 or more studs are needed since the load-sharing of the studs furthest from the opening is not efficient.

When the stud pack ends up being more than 3 studs, or the gauge needs to be increased, it may be wise to consider another option. The most economical design may include structural steel in place of stud packs, especially when requirements in D110 may result in a wall of studs!