Masonry wall openings are a common location for diagonal cracks which can result from improperly detailed lintels. Steel lintels can be properly detailed to span openings in masonry walls, but would a masonry lintel be more efficient?

In the September 2024 SEU session, Scott Walkowicz, PE, from Walkowicz Consulting Engineers, presented Masonry Design and Detailing: Using Your Owner’s Money Wisely. Scott discussed the structural performance benefits and building improvements achieved through the use of masonry, as both a structure and an outer envelope. He identified ways to reduce cost and minimize material waste in masonry design and detailing. He also examined masonry details to create functional, durable, and constructable masonry assemblies.

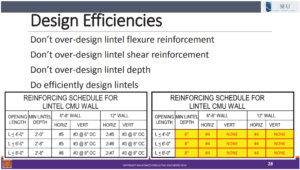

Scott recommends using masonry lintels in masonry walls, as opposed to steel lintels. Steel lintels can cause many issues in masonry walls and are rarely needed. Differential movement is among the most problematic issues when using steel lintels in masonry walls. Also, in the event the steel lintel is accidentally or erroneously restrained, very large forces can develop in the steel and cause significant cracking in the masonry wall. Masonry lintels provide a more cohesive design and can be designed to resist significant forces. As you can see below, an efficient masonry lintel design requires minimal reinforcement to span short distances. When necessary, reinforcement can be added to increase the capacity of masonry lintels carrying significant forces. However, engineers should consider their typical lintel schedules to be sure efficient reinforcing is specified to minimize the overall project cost.

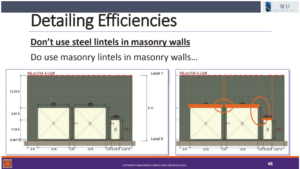

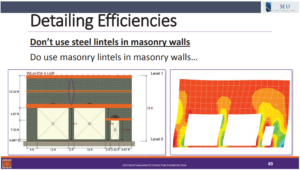

Masonry lintels also contribute to stronger walls. As you can see below, several control joints are necessary in the wall using steel lintels. These joints reduce the capacity of the wall, increase the chance of differential movement between the lintel and the wall, and increase the chance of cracks in the masonry. Replacing the steel lintels with masonry bond beams and lintels create strong wall action, as shown in the finite element model on the slide below. This wall is more efficient and results in a better product.

As a best practice, engineers should eliminate steel lintel schedules as typical details on their masonry projects and replace them with an efficient typical masonry lintel schedule. When required for heavy loads, additional masonry lintel details are capable of carrying significant loads and should be designed for specific loading conditions. Efficient masonry lintels used throughout a masonry project will reduce the overall cost for the owner and minimize problems typically created by steel lintels.