Steel joist bridging plays an important role in the overall strength of a joist system. Bridging provides lateral stability during erection and when chords are not fully braced during the application of loads. However, conflicts are common when locating bridging on drawings, in the field, and during retrofits. How should engineers address or avoid these common occurrences?

In the November 2021 SEU Session, Tim Holterman, PE, SE, from Canam Steel, and Bruce Brothersen, PE, SE, from Vulcraft, representing the Steel Joist Institute, presented Bridging and Steel Joists (How it Works and What to Work Around). They covered the types and roles of bridging and the governing criteria for bridging spacing and sizing. Connection details, common conflicts and resolutions were also highlighted.

Tim and Bruce addressed many common pitfalls in regard to steel joist bridging and provided guidance for these problematic situations. Below are several frequently asked questions along with an explanatory graphic to solve these dilemmas.

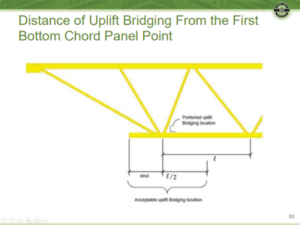

How close is close enough to the first bottom chord panel point for the first row of uplift bridging?

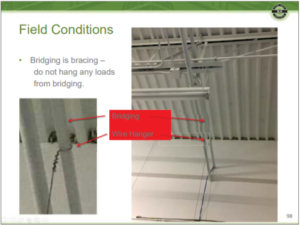

Can I hang a supported ceiling from steel joist bridging?

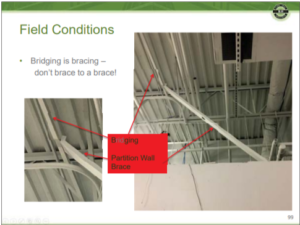

Can I brace the top of a partition wall to steel joist bridging?

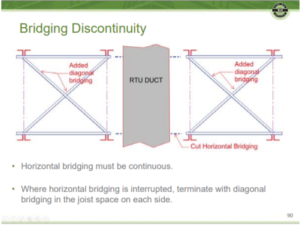

How should I address a bridging discontinuity for ductwork or other equipment?

Can an additional, external wind force be transferred through the joist bridging?

Bridging is bracing and it is essential to the structural integrity of the steel joist system. Engineers can ensure their joist system stays structurally sound by proper placement of bridging, as well as avoiding discontinuities or applying any additional loads to these slender braces.